Visit us at The Foodex Manufacturing Solutions 24th – 26th April!

Stand G50

The UK’s leading trade event for the food and drink processing, packaging and logistics industries is back for 2023! Foodex Manufacturing Solutions will explore the hottest trends that are driving the sector, showcase the latest products and services to improve operational efficiency as well as provide the opportunity for buyers to connect with potential suppliers through interactive events and discussions.

We will be joining our sister companies Unitech Engineering Ltd and Unitech Washing Systems to provide a one stop shop for you production and processing requirements.

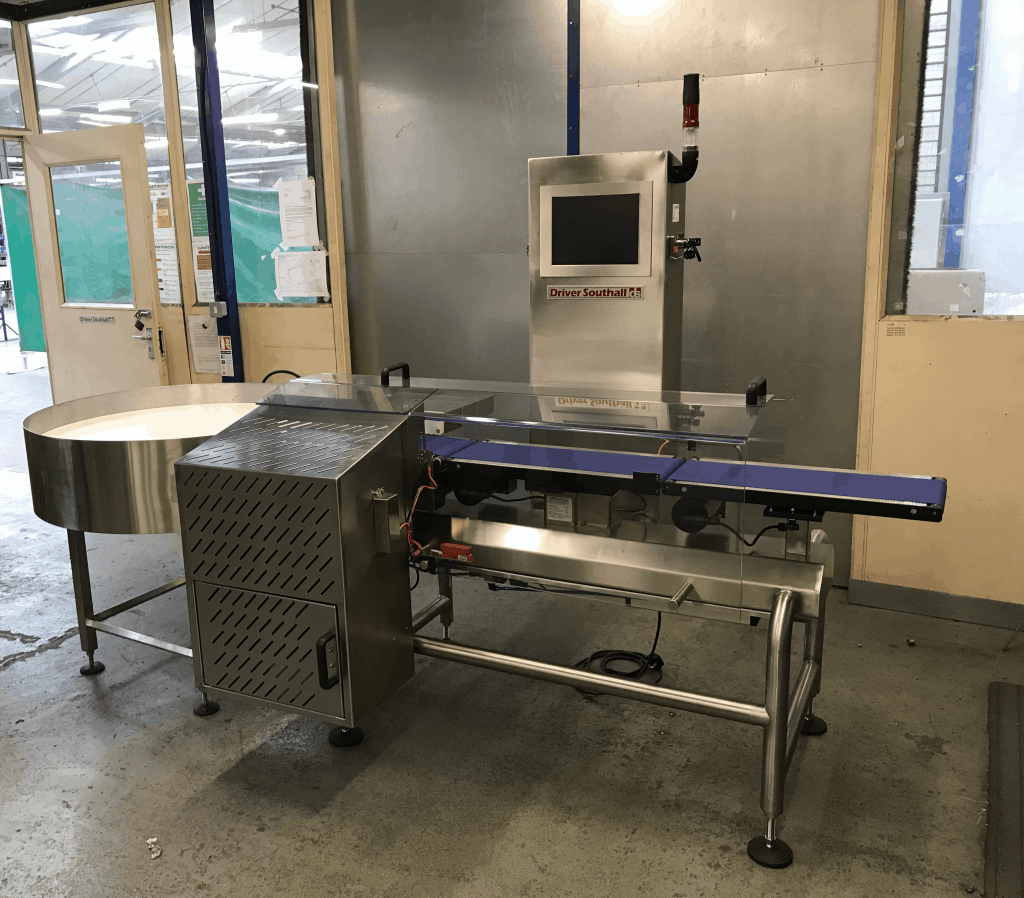

Driver Southall will be demonstrating our latest inspection systems , specifically designed for the food and beverage sector. We will also be demonstrating some of the latest weights systems that we have to offer.

To find out more about Driver Southall and or other products offered within our group, visit us on stand G50

For more details on the event and how to get there please visit the Foodex Website Here

Can’t Wait? Get in contact with us straight away

Email: sales@driversouthall.co.uk

Tel: 01543 687090