We have been manufacturing checkweighers in the UK for more than 50 years. In this time we have supported a number of businesses in various different industries including Food and Beverage, Pharmaceutical and automotive. One local company we have always supported was Eley, a producer of ammunition based near Birmingham who has been using our Guardian 90 Checkweighers for nearly 30 years!

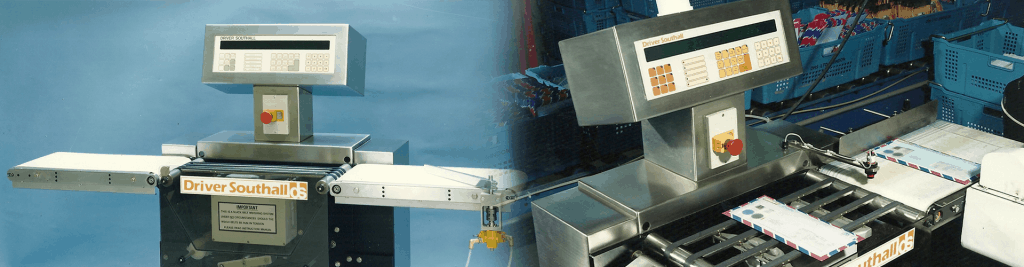

Guardian 90 Checkweigher

We first installed three Guardian 90 checkweighers at Eley in the 1990’s. The machines has been serviced and calibrated twice a year since they was first installed. Despite the machines being functional, parts for these machines are becoming more difficult to source. . This meant that should a breakdown occur it could be difficult or impossible to get the older system running.

Eley made the decision to replace one of the existing Guardian 90 Checkweighers with a new machine.This was largely due to an increase in linespeed and it would remove the concern about obsolete parts. .

Design Brief

The design brief was simple. To manufacture a reliable cost effective checkweigher which is easy to use and guaranteed to last. We needed to make the checkweigher cost effective and maintain an uptime of 98%

Several meeting took place looking at the design of the machine. We opted to keep the design similar to one that had been previously used with small changes made to make the machine easier to service.

The machine was manufactured using technology from our latest range of DS4 Checkweighers . However, on this low cost checkweigher we decided to use a simple controller. This would not affect the performance of the unit but would help keep costs low.

We kept the customer updated on the progress of the machine and updated them if things changed.

Customer PDI

Frederic Sage, Project manager carried out machine inspection and independent tests. All of the tests were successful and the customer has happy with the build quality and finish of the machine.Overall, the machine achieved an accuracy of +/- 0.5 grams on a 200 gram pack @ 140 Packs Per Minute.

Frederic Sage had this to say:

“In summary: The project was conducted professionally and was delivered on time and within budget. The installation date was fixed so regular updates were given on the progress of the machine.

Some minor issues did arise during the pre-acceptance at Driver Southall, but Jamie and his team did overcome them the same day, hence not impacting on the delivery date. They delivered and installed the machine on time.

Since then the machine has been running with no downtime.”

This is the first of three machines that Eley is looking to replace. We are currently quoting several of these units to customers using Guardian 90 Checkweighers who don’t require retail specification.

With the support of our sister company Unitech Engineering and other companies with Unitech Industires we aim to offer a complete turnkey solution for almost any packing or processing line.

If you have any requirements for Checkweighers, Metal Detectors or combination systems then feel free to give us a call on 01543 687090 or email us at Sales@Driversouthall.co.uk