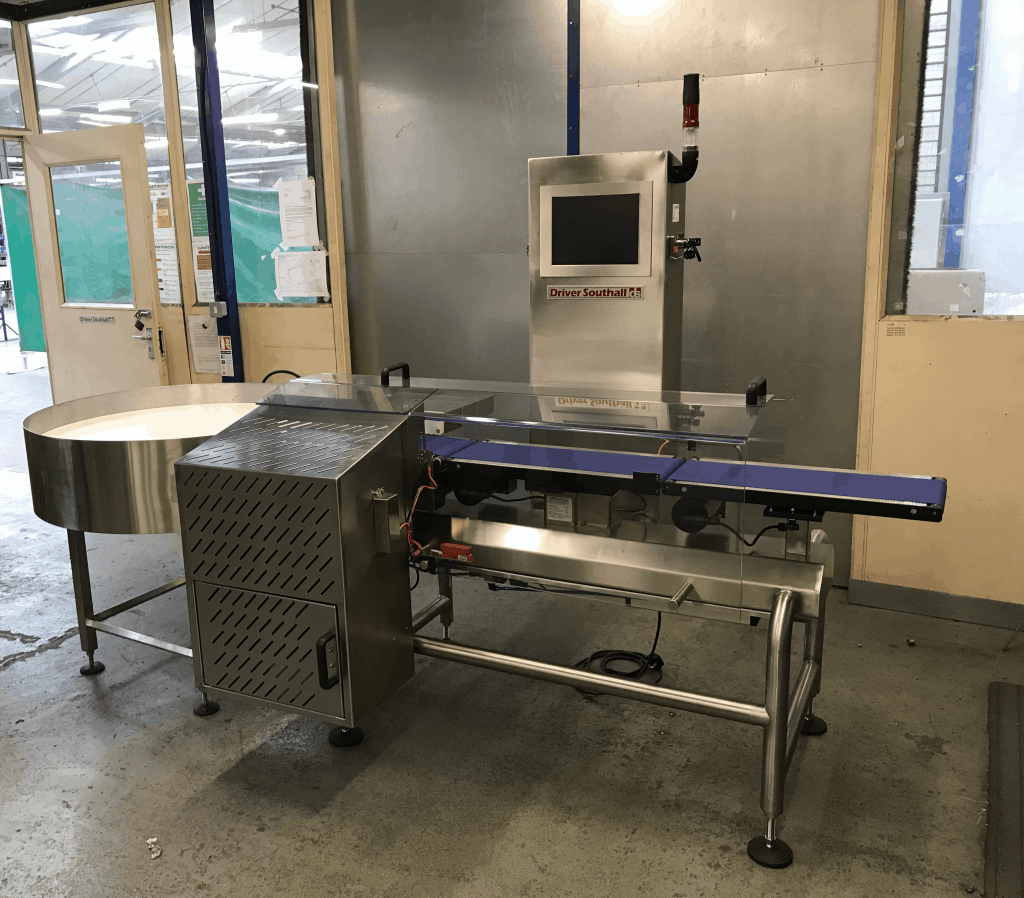

Another two checkweighers have been issued for production today for a repeat customer of Driver Southall. Our checkweighers are designed to suit each individual application with the aim to maximise throughput, accuracy in the space available. The machine above has an overall footprint of 1204mm x 1000mm and can handle a 200mm pack at speeds exceeding 120 packs per minute. This can be fitted with a variety of reject mechanisms which are carefully selected and installed for each product.

If you have any requirements for checkweighers, metal detection systems, combination systems or vibratory conveyors then please don’t hesitate to give the office a call on 01543 687090 or drop up as line at Sales@Driversouthall.co.uk