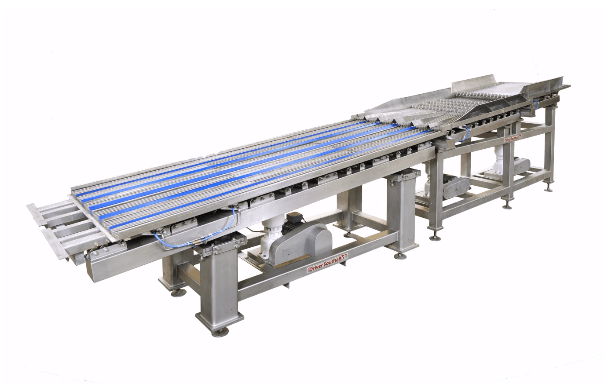

Fish Finger Laning Conveyor

Driver Southall was asked to produce a laning conveyor for a company manufacturing fish fingers. The conveyor should take bulk product and sort them into lanes ready for cartoning. Driver Southall designed a custom made solution which vibrates the product down the conveyor but also spreads the product out on the first…

Read more